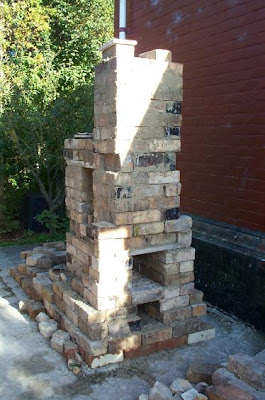

Firing the Wood fired kiln 01

I bricked up the kiln door and sealed the gaps between the bricks with a goodly smear of clay.

I bricked up the kiln door and sealed the gaps between the bricks with a goodly smear of clay.Around 4.30 this evening I lit a small fire in a temporary extension to the fire box. I allow this little fire to bring the temperature up to about 100 degrees Centigrade (212 F). I then keep the fire ticking over for a few hours to dry out any pots that might still have moisture in from the glazing, and to pre warm the kiln structure.

To the left of the doorway in the picture, I have a second hand pyrometer to give me a fair idea of the temperature throughout the firing, and a round clock below it. The clock is very important, as it allows me to keep a log of the whole firing, and enter in the temperature on to some graph paper every quarter of an hour. Without the log, it would be hard to know if the kiln was gaining temperature too fast or too slowly, and it is very handy and a good diagnostic tool, to be able to compare logs from previous firings.

In addition to the pyrometer, I use special ceramic cones to help me determine when I am at the right temperature for the pots that are being fired. The cones are (at a guess) about three inches high, and are made out of much the same ingredients as glazes are made out of. They are carefully formulated to flop over when certain temperatures are reached.

There is a nice wikipedia article about pyrometric cones if you click on the link just provided.

Comments

Patti, the clay that fills in the cracks does dry out mighty fast as the bricks heat up, it is usually accompanied by a haze of steam, which is nice to watch. Most of the clay stays put and effectively blocks up anywhere that air might have got through. Sometimes you have to be prepared to patch the odd bit as the firing progresses.

Linda, I'll try to remember to say a bit more about cones, as they are rather interesting, and have a fascinating history. I'll keep you updated about the rate of climb of the temperature as we go, and probably post a little graph when we are finished.

Must get back to it now, Peter