My Woodfired Kilns, all 7.

Kiln Number One.

I had not seen a wood fired kiln, other than in photographs, before I built one. My friend, Peter Watson who got me started with potting, kindly lent me books and magazines. One book, "The Craft Of The Potter" by Michael Casson, had a plan in it for building a small wood fired kiln that could be used for raku or small earthenware pots. I bought some second hand fire bricks from a demolition yard, and made my first kiln, largely based on the plan in Michael Casson's book.

I had no idea if it would work, and was concerned that it might be too smoky, so I built it almost out of sight between the back of our house and the shed where it was screened from the main road and from neighbours. I fired it once to 1100 degrees Centigrade in little over 2 and a half hours. The clay that I put the cones in exploded and scattered bits of cone and clay over some of the pots and glaze test tiles that I put in, but I was really excited by the apparent ease of achieving a useful temperature and demolished the kiln so that I could use the bricks as part of something much bigger!

Kiln Number Two.

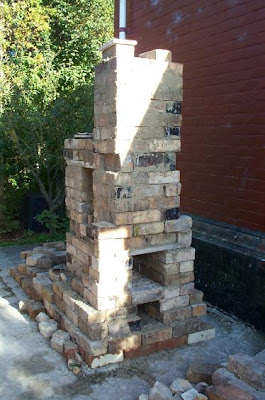

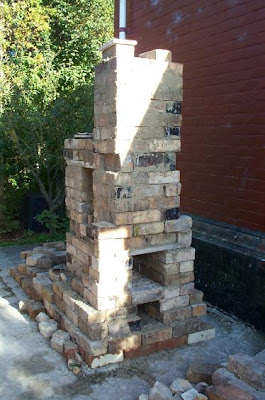

Kiln number two was a round up draft kiln. The chamber had a beautiful chequered floor that I gleaned from Michael Cardew's "Pioneer Pottery". Some other ideas were gathered from a book on making kilns by Ian Gregory. I also had ideas of my own, notably an attempt at a modified Bourry firebox. In its favour, the kiln did look very sculptural, and rather pretty in some lights, and there was opposition from Laura to the idea of pulling it down, but the fact of the matter was that the kiln didn't work!

Kiln Number Three.

(The photo above shows my friend and teacher, Peter Watson, and myself examining the results of a firing of kiln number three.)

(The photo above shows my friend and teacher, Peter Watson, and myself examining the results of a firing of kiln number three.)

I added a chimney to kiln number two where the firebox had been and converted it from an up draft to down draft kiln. I removed the top of the chamber and made a roof for it with an old kiln door. I made a new firebox on the same side as the kiln door. The firebox was of greater area than on the previous kiln, but was shorter and squarer. The firebox had to be partly demolished to enable the kiln to be loaded and unloaded, which was annoying. The firebox was also horribly low which meant that a day's stoking was really hard on the back and the knees. I did managed to nurse the kiln to around 1060 degrees Centigrade after a stoke of 8 or 9 hours, and fired some rather under done earthenware pots. I demolished all but the chimney of this kiln after one firing and designed something that would be easier to stoke.

Kiln Number Four.

Kiln Number Four was the first kiln that really worked. With the knowledge gained from the first three attempts I went back to the drawing board. I wanted a kiln that would be easy to stoke, and that would give a strong flame flashing effect on the pots. I put the firebox crosswise, and, dispensing with a bag wall, fed the flame in near the top of the chamber, and zigzagged it downwards to be collected at the bottom of the chamber below the lowest kiln shelf. On the way to the chimney was a second small chamber that had room for one or two pots. I used an old kiln door for the roof of the chamber, and recycled fire bricks for the main kiln construction with an outer layer of ordinary red house bricks for insulation. I had a really successful, and enjoyable firing of my first earthenware watering cans and some other smaller pots. The work was fired raw, and I found the firebox a pleasure to stoke, and the temperature rise easy to control.

Kiln Number Four was the first kiln that really worked. With the knowledge gained from the first three attempts I went back to the drawing board. I wanted a kiln that would be easy to stoke, and that would give a strong flame flashing effect on the pots. I put the firebox crosswise, and, dispensing with a bag wall, fed the flame in near the top of the chamber, and zigzagged it downwards to be collected at the bottom of the chamber below the lowest kiln shelf. On the way to the chimney was a second small chamber that had room for one or two pots. I used an old kiln door for the roof of the chamber, and recycled fire bricks for the main kiln construction with an outer layer of ordinary red house bricks for insulation. I had a really successful, and enjoyable firing of my first earthenware watering cans and some other smaller pots. The work was fired raw, and I found the firebox a pleasure to stoke, and the temperature rise easy to control.

The top of the chamber fired hotter than the bottom, this was as I predicted. More importantly, the top of the chamber had really good flame flashing, and the pots that were on the top shelf toasted up beautifully.

It was with real sadness that I later demolished this kiln and made way for kiln number five, as kiln four had real potential. The main problem was the small chamber. Also, the strong flame flashing suited unglazed work, but would have been a problem for glazed pots.

Kiln Number Five.

Kiln Number Five, a round up draft kiln, does work quite well. The firings take about 5 to 6 hours to get to 1200 degrees centigrade in the lower part of the chamber. The kiln is quick to cool down, and can be unloaded the day after firing it. The kiln has three levels of triangular kiln shelves that are arranged around a central prop like segments of an orange. Little gaps in between the shelves allow for the heat and flame from the firebox to rise through the chamber. The lowest part of the chamber is much hotter than the top, but I can rely on about 1200 degrees on the bottom shelf, around 1150 on the middle, and about 1060 on the top shelf. Glazed pots can turn out well in this kiln, and pots can also get strong flame flashing on the lower shelf. It is possible to fire too quickly with this kiln (in excess of 400 degrees centigrade per hour gain), or to loose heat fast if not fired with care. Above 800 degrees centigrade, the kiln is also likely to go into strong reduction if too much wood is put on at a time.

I still have this kiln, but have made kiln number six, an even firing down draft design, to get to stoneware temperatures.

Kiln Number Six.

Kiln Number Six is my production kiln. I mostly fire it to cone 11 to 12 in about 12 to 13 hours, although it could get there much quicker. The kiln was built mostly with new fire bricks. There is a layer of hard brick within the chamber that is backed up with K23 insulating fire brick. K26 insulating bricks form the arch. The kiln was inspired by a much smaller gable arched wood kiln designed by Jim Schuld that I saw in a Ceramics Monthly magazine. My kiln differed quite a bit from his design, but I liked his fresh ideas and his use of unusual materials, and the article was a great help in getting me started. I will write an article about my kiln, with some diagrams, so won't go on at length here.

Kiln Number Seven.

(Top photo shows my friend, Dave Sharp, casting his expert eye over one of the raku pots. Dave is an enthusiastic raku potter.)

(Top photo shows my friend, Dave Sharp, casting his expert eye over one of the raku pots. Dave is an enthusiastic raku potter.)

Kiln Number Seven, is a small raku kiln. It is capable of reaching 1000 degrees centigrade in about two and a half to three hours. Whilst taking out a load of pots the temperature in the chamber drops to about 600 degrees, but is back up to 1000 degrees in 20 to 25 minutes. I use a cross draft firebox, and, because of its short length, the front part of the chamber is fairly oxidizing and the back part tends towards reduction.

I had not seen a wood fired kiln, other than in photographs, before I built one. My friend, Peter Watson who got me started with potting, kindly lent me books and magazines. One book, "The Craft Of The Potter" by Michael Casson, had a plan in it for building a small wood fired kiln that could be used for raku or small earthenware pots. I bought some second hand fire bricks from a demolition yard, and made my first kiln, largely based on the plan in Michael Casson's book.

I had no idea if it would work, and was concerned that it might be too smoky, so I built it almost out of sight between the back of our house and the shed where it was screened from the main road and from neighbours. I fired it once to 1100 degrees Centigrade in little over 2 and a half hours. The clay that I put the cones in exploded and scattered bits of cone and clay over some of the pots and glaze test tiles that I put in, but I was really excited by the apparent ease of achieving a useful temperature and demolished the kiln so that I could use the bricks as part of something much bigger!

Kiln Number Two.

Kiln number two was a round up draft kiln. The chamber had a beautiful chequered floor that I gleaned from Michael Cardew's "Pioneer Pottery". Some other ideas were gathered from a book on making kilns by Ian Gregory. I also had ideas of my own, notably an attempt at a modified Bourry firebox. In its favour, the kiln did look very sculptural, and rather pretty in some lights, and there was opposition from Laura to the idea of pulling it down, but the fact of the matter was that the kiln didn't work!

Kiln Number Three.

(The photo above shows my friend and teacher, Peter Watson, and myself examining the results of a firing of kiln number three.)

(The photo above shows my friend and teacher, Peter Watson, and myself examining the results of a firing of kiln number three.)I added a chimney to kiln number two where the firebox had been and converted it from an up draft to down draft kiln. I removed the top of the chamber and made a roof for it with an old kiln door. I made a new firebox on the same side as the kiln door. The firebox was of greater area than on the previous kiln, but was shorter and squarer. The firebox had to be partly demolished to enable the kiln to be loaded and unloaded, which was annoying. The firebox was also horribly low which meant that a day's stoking was really hard on the back and the knees. I did managed to nurse the kiln to around 1060 degrees Centigrade after a stoke of 8 or 9 hours, and fired some rather under done earthenware pots. I demolished all but the chimney of this kiln after one firing and designed something that would be easier to stoke.

Kiln Number Four.

Kiln Number Four was the first kiln that really worked. With the knowledge gained from the first three attempts I went back to the drawing board. I wanted a kiln that would be easy to stoke, and that would give a strong flame flashing effect on the pots. I put the firebox crosswise, and, dispensing with a bag wall, fed the flame in near the top of the chamber, and zigzagged it downwards to be collected at the bottom of the chamber below the lowest kiln shelf. On the way to the chimney was a second small chamber that had room for one or two pots. I used an old kiln door for the roof of the chamber, and recycled fire bricks for the main kiln construction with an outer layer of ordinary red house bricks for insulation. I had a really successful, and enjoyable firing of my first earthenware watering cans and some other smaller pots. The work was fired raw, and I found the firebox a pleasure to stoke, and the temperature rise easy to control.

Kiln Number Four was the first kiln that really worked. With the knowledge gained from the first three attempts I went back to the drawing board. I wanted a kiln that would be easy to stoke, and that would give a strong flame flashing effect on the pots. I put the firebox crosswise, and, dispensing with a bag wall, fed the flame in near the top of the chamber, and zigzagged it downwards to be collected at the bottom of the chamber below the lowest kiln shelf. On the way to the chimney was a second small chamber that had room for one or two pots. I used an old kiln door for the roof of the chamber, and recycled fire bricks for the main kiln construction with an outer layer of ordinary red house bricks for insulation. I had a really successful, and enjoyable firing of my first earthenware watering cans and some other smaller pots. The work was fired raw, and I found the firebox a pleasure to stoke, and the temperature rise easy to control.The top of the chamber fired hotter than the bottom, this was as I predicted. More importantly, the top of the chamber had really good flame flashing, and the pots that were on the top shelf toasted up beautifully.

It was with real sadness that I later demolished this kiln and made way for kiln number five, as kiln four had real potential. The main problem was the small chamber. Also, the strong flame flashing suited unglazed work, but would have been a problem for glazed pots.

Kiln Number Five.

Kiln Number Five, a round up draft kiln, does work quite well. The firings take about 5 to 6 hours to get to 1200 degrees centigrade in the lower part of the chamber. The kiln is quick to cool down, and can be unloaded the day after firing it. The kiln has three levels of triangular kiln shelves that are arranged around a central prop like segments of an orange. Little gaps in between the shelves allow for the heat and flame from the firebox to rise through the chamber. The lowest part of the chamber is much hotter than the top, but I can rely on about 1200 degrees on the bottom shelf, around 1150 on the middle, and about 1060 on the top shelf. Glazed pots can turn out well in this kiln, and pots can also get strong flame flashing on the lower shelf. It is possible to fire too quickly with this kiln (in excess of 400 degrees centigrade per hour gain), or to loose heat fast if not fired with care. Above 800 degrees centigrade, the kiln is also likely to go into strong reduction if too much wood is put on at a time.

I still have this kiln, but have made kiln number six, an even firing down draft design, to get to stoneware temperatures.

Kiln Number Six.

Kiln Number Six is my production kiln. I mostly fire it to cone 11 to 12 in about 12 to 13 hours, although it could get there much quicker. The kiln was built mostly with new fire bricks. There is a layer of hard brick within the chamber that is backed up with K23 insulating fire brick. K26 insulating bricks form the arch. The kiln was inspired by a much smaller gable arched wood kiln designed by Jim Schuld that I saw in a Ceramics Monthly magazine. My kiln differed quite a bit from his design, but I liked his fresh ideas and his use of unusual materials, and the article was a great help in getting me started. I will write an article about my kiln, with some diagrams, so won't go on at length here.

Kiln Number Seven.

(Top photo shows my friend, Dave Sharp, casting his expert eye over one of the raku pots. Dave is an enthusiastic raku potter.)

(Top photo shows my friend, Dave Sharp, casting his expert eye over one of the raku pots. Dave is an enthusiastic raku potter.)Kiln Number Seven, is a small raku kiln. It is capable of reaching 1000 degrees centigrade in about two and a half to three hours. Whilst taking out a load of pots the temperature in the chamber drops to about 600 degrees, but is back up to 1000 degrees in 20 to 25 minutes. I use a cross draft firebox, and, because of its short length, the front part of the chamber is fairly oxidizing and the back part tends towards reduction.

Comments

I have come to potting rather late (I started in my mid 40s) so I have felt the need to make up for lost time, hence the somewhat frantic pace of kiln building. In some ways I think I learn faster then I did when I was in my teens (maybe we learn cunning as we get older!), but the body has more limitations now. I do wish I could be an apprentice potter for a few months at least to get more idea of the everyday routine of a production pottery,and also see other people making pots. I'm not sure that anyone would be interested in taking on an old fellow like me though.

I am still using an electric kiln for some of my work, and will post some photos of the latest glaze firing soon.

Best Wishes, P.

I've enjoyed my apprentice time at the clay center where I am. I've learned a lot not just from the facility - but from all of the folks who take classes there. I also came to clay late & have only been working in clay for about 10 years now. Being older does help you understand priorities - maybe that's why we learn faster -- and make a good apprentice -- don't let age stop you from trying to find an apprentice position.

I'm very interested in seeing your electric kiln work & glazes. Looking forward to those photos.

Thank you for following my blog, and for your comment. It is good to hear from you. It is also good to hear from someone in Poland. There are quite a lot of Polish people in New Zealand, and my wife (although not herself Polish) is invited on a regular basis to exhibit her paintings with the Polish Society in Dunedin.

I have indeed been fortunate to have been able to build wood fired kilns. I do love what wood and wood ash can do to a pot when it is fired, and enjoy the way that wood firing can be such a continuation of the creative process.

I have enjoyed looking at your blogsite. Sadly, I do not speak Polish, but it is good to see the photos. You have very interesting work.

I tried to post a comment on your site, but could not work out how to do it.

Best Wishes, Peter.

claire

Welcome to my site. I am sorry to say that I know nothing (as yet!!) about metal working or blacksmithing, so I really can't help you regarding kilns for that. I had a quick search online with Google for blacksmith forge plans, and came up with a lot of photos and some plans when I did a Google "Images" search.

I noticed that you said "kiln", rather than "forge" or "furnace". I found a site that might be of interest (??)

http://www.artfulbodgermetalcasting.com/3.html

Sorry not to have been of more help, but I am sure that there will be someone out there who will have useful information for you.

Good luck with it. It would be nice to hear how you get on.

P.

I would like to build my own kiln but I don't have a large backyard.

You second kiln looks small enough.

It would wonderful to see the construction drawings or something that could help to copy you kiln.

Faithfully yours,

Ilia,

Minsk, Belarus

Sirius2@rambler.ru

Lovely to hear from you, welcome to my site.

Sorry not to reply sooner, I have been very busy here over the last few days, and have had not much time on the computer. Unfortunately I did not draw a plan of the 5th kiln, but just made it with what I had available at the time.

I did find some nice looking plans of a simple round updraft kiln in a book called "Self Sufficient Pottery" by Judy Cunningham-Smith and Mollie Herbert. The book was published in 1979, but there are a copies available at very reasonable prices second hand through Amazon.com and AbeBooks.com

Sorry not to be more helpful now, but I am rather tired after a long day. I will try to send you some more information to your Email address.

Best Wishes,

Peter

Good to hear from you. I was astonished by getting to more than 1000 C so easily, and it was really exciting to find that it could be done. Good luck with your BBQ kiln, it sounds fun, do let us know how it works out! P

Using clay from your own backyard is quite a big topic for me to answer properly as a short comment, I would really need to do a post on it. I had a very quick look on line as I know that other people will have put together "howto" advice on this. One site that could give you the information that you need to get started is

http://www.practicalprimitive.com/skillofthemonth/processingclay.html

This has good information and step by step photos of processing clay that you may find helpful.

The clay that is in most people's backyards where I live (and gardener's complain about!!) is a nice earthenware that fires to the cone 01 - 2 range that you mention.

Good luck! P.

My next question and suggestion; have you ever heard of the Rocket stove? We have been learning about them and using them for a few years and the concept is best found on a page that I probably can't put up or it will be tagged as spam. But, go to Google and type, rocket stove, Paul Wheaten,Rich soil. This is the Permies site which has loads of neat DIY ofo, and this rocket stove concept is the best thing I have found to heat your home, greenhouse, even tent. The "rocket" part of the stove is the heat riser, which is above the woodfeed.(which is vertical and the fire is drawn in sideways. ) and that area because of the vortex, creates amazing smoke dissipating abilities. So the "mass" of the mass heater can then absorb the rest of the heat with long lasting comfort in the home. watch the videos and see. But there must be a way to marry these concepts with a kiln!

Also, the gross reduction in smoke will make you a better neighbor.

I don't usually publish adverts here, but in this case I'll bend the rules, the Google search that I did confirms what you say, the Rocket stove looks a great idea! I am always interested in ways of using fuel more effectively. Thanks for the information. P

It should be fairly easy to build a kiln for terra cotta temperatures. I was wondering how many 20" square by 24" tall you were wanting to fire at a time? The other important thing that could be a factor in kiln design is if you are out in the country somewhere with no near neighbours and no fire restrictions? Or if you are in a town?

The Kiln Book, by Fredrick Olsen is one of the best starting places for getting an overview of kiln design. You will find that book at amazon.com, or many other book sellers. Many potters built kilns based on Olsen's fast fire wood fire kiln, but there is good information about tradional kilns in the book that could suit earthenware better.

One problem I can think of straight away for you with a "modern" down draft fast fire design, is the size of kiln shelves. Your 20" square work would essentially take up one large kiln shelf, and an "efficient" wood fired kiln with a chamber of maybe 20 - 30 cubic feet, might not fit many of your pots in it. It is possible to fire a kiln like that with very little smoke being generated (which is good if you have neighbours or fire restrictions), but you may find a simple updraft design a much better proposition if you were firing lots of larger earthenware pots. You would almost certainly generate more smoke though! I will email you as well with this.

Best Wishes,

P

im a young potter that has been raised in and around earthenware all my life.Now a young potter of 33 years old and over 25years of potting i have been searching for small designs of wood fired kilns for a couple of months and was wondering if you could send me in the right direction for advice so many questions i have about this process in my head any ideas would be appreicated

Good to hear from you, thank you for having a look at the blog and for writing in. One very practical book that springs to mind is, "Kiln Construction: A Brick by Brick Approach" by Joe Finch.

If I had found a copy of this when I first started trying to build a wood fired kiln, I think I would have made even faster progress. This is a fairly short book, and you will easily read through in an evening, but the practical examples of kilns that he gives are a good starting point, and look like they would work well and be easy to build and to fire. The kilns that are described in the book are for wood or for gas, or for a mixture of both. The kilns use modern materials, such as insulating fire bricks, and would fire economically.

In one of my comments above this I also mention "The Kiln Book" by Fredrick Olsen, and this is also a very worth while book to study. This is a much longer book, and has lots of information about kilns in general, as well as specific examples. Many potters built versions of the Olsen Fast fire kiln that is covered in this book. The kilns by Joe Finch seems to me to be a further refinement of Olsen's Fast Fire kiln, and it is interesting to compare them.

Hope all that helps.

Best Wishes, P

I came across your blog while searching for wood kiln plans. I would love to build one similar to your 6th kiln. Would you happen to have plans for that one? Or suggestions for building plans? I'm enjoying your lovely blog!

Adele

Glad that you are enjoying the blog, thank you for writing in. I never did a complete plan for kiln number six, as the kiln evolved quite a lot when I was building it, and over later years. Because I used a mixture of new and recycled materials, and had only second hand kiln shelves of slightly strange sizes, I had to adjust my ideas for a kiln to suit what I was building it with!

I think that the book I mentioned to someone else in the comments above, is a good place to start, "Kiln Construction: A Brick by Brick Approach" by Joe Finch. The kilns in this book are quite straight forward and look like they should work well. Jo Finch also uses materials in an efficient and economical way, so you get a lot of kiln for your investment!

I had a look at your web site and was delighted to see what had been achieved thus far with the pottery.

Really the best solution would be for a potter who has appropriate kiln building experience to go and help you in Honduras, or failing that, it would be good for members of your team to find someone who is wood firing and see if you can observe and help out in a firing. There is quite a lot to learn in order to fire a kiln well, and also much that needs to be learnt about kiln building.

I don't know how difficult it is to get kiln building materials into Honduras, but I am thinking that you may want to take the "traditional" potter's approach of building a kiln from local materials.

If the local clay is earthenware and it fires to a red or brown colour at fairly modest temperatures, then a simple updraft kiln could be built. This would be roughly circular with an open top and could be constructed of ordinary earthenware house bricks, or adobe brick or rammed earth made from the same clay that your pottery is made of (and probably mixed with sand and straw). Probably 3 simple fire boxes could be constructed around the perimeter of the kiln wall. The kiln would be packed with earthenware pottery, and have a temporary roof built over the pots with broken pots and turfs. Many traditional kilns were made like this. You could fire this to 1000 degrees Centigrade (1832 F) which may be enough to fire some local clays.

I did a quick Google search for simple traditional/primitive updraft kilns,

Here is a short article about a project that was done with school children, the small updraft kiln would reach 1100 C (2012 F)

http://www.woodroffe.dorset.sch.uk/ART.COLLEGE/Walking%20Stones%20Axe%20Valley/Walking%20Stones.htm

I also found this on Egyptian traditional kilns that shows much larger updraft kilns.

https://escholarship.org/uc/item/47x6w6m0#page-1

Hope this may give some useful ideas for you to think about.

Good to hear from you all the way from the Blue Ridge Mountains! You live in a beautiful part of the world. Building wood fired kilns can be as simple or as complicated as you like. It is much easier to build something that will fire to raku and earthenware temperatures, and somewhat more tricky making something that will fire higher than that.

The first question to ask yourself is "what temperature to I want to fire to?"

Another is, "what do I want the wood fired pots to look like?" Do you want toasty pots that have obvious flame flashing and a build up of ash? Or do you want something quieter?

Another question would be, "what kiln building materials do I have already?"

Another would be, "Do I have close neighbors that would complain about wood smoke?"

I would recommend making a simple kiln to start with, that you might fire to raku temperatures, or almost earthenware..... I published a plan for a kiln like this on my blog on October 14 2009

http://opopots.blogspot.co.nz/2009/10/raku-kiln-for-armelle-getting-pots.html

A slightly more advanced kiln, that will get you to earthenware temperatures, and possibly to around cone 6 or beyond, would be one that I published on July 13, 2009

http://opopots.blogspot.co.nz/2009/07/kiln-for-claire-part-two-small-wood.html

This uses some insulating fire brick for the chamber of the kiln, and I have shown a blanket of ceramic fiber on top... you could use a much thinner layer of fiber, or some insulating fire bricks up there.

Some of the other people that commented on this site have also asked a similar question to yours about kiln building, and I recommended a couple of books to help get them started,

"Kiln Construction: A Brick by Brick Approach" by Joe Finch. The kilns in this book are quite straight forward and look like they should work well. Jo Finch also uses materials in an efficient and economical way, so you get a lot of kiln for your investment! "The Kiln Book" by Fredrick Olsen, this is also a very worth while book to study

Best Wishes, P

"Late to the party" or not, you are very welcome!

Exploding pots is usually due to moisture in the clay and the generation of steam! After loading the kiln I usually light a very small fire in the ash pit of my kiln in the evening of the day before I plan to fire. I keep this tiny fire made from just a few twigs burning for a couple of hours, and have the kiln dampers wide open so that the pots can dry completely and warm, moist air pass out of the kiln easily. I let the kiln get to nearly 100 degrees C, but no more in this warming period. Then I let the fire go out, close the chimney damper to about one third, and go to bed! Next morning, really early, I light the kiln, and I usually find that it is still 40 to 60 degrees C (it is well insulated). I light another small fire and let the temperature in the kiln climb at about 100 degrees C per hour for the first couple of hours until it is well over 200 C (and most of the fear of pots exploding due to moisture is past). After that I may fire faster, but it depends on the size of the work that is in the kiln. Small pots may be very happy climbing at well above 200 degrees C per hour especially when above red heat. Larger pots and wide bowls or platters require more care!

Very pleased to hear that you are giving wood firing and kiln building a try.

All the Best,

Peter

Very good to hear from you, thank you for your comment. I have just been having a very interesting time visiting your website, reading some of your essays and looking at your sculpture. The Greek style updraft looks really great and I wish you lived closer as it would be fun to see it in person. I really enjoyed the updraft kiln that I made... I think it was kiln Number 5 at the time, the thing was probably a little overpowered and would climb at a great rate with the lower pots getting to low stoneware temperature in about 4.5 hours! We had some quite nice pots from that kiln as it gave good flame flashing effects. I did major work on my current kiln over the last year to make it easier for me to fire. My own back and general health is also not much good, so, like you, I am having to find "clever" ways to adapt to things.

Very Best Wishes,

Peter

Will

Digging shards and being around good clay really is a wonderful foundation for a life working with pots and sculpture! The "plague" also got me into the bread making habit! I found a simple ciabatta recipe online, and most of the bread I've baked since has been based on that one, with some improvisation as the mood takes me. Sometimes I put the dough into an oven tray and let the bread grow without constraint, and other times I bake in a round cake tin! It is fun to be free of producing oblong blocks each time! I'll check back to your web site from time-to-time and look forward to seeing the replacement of the kiln dome. I always intended a Greek style kiln of my own at some point, there is a very old illustration of a Greek kiln that appears to show a kiln chamber that is entirely spherical inside, with a curved floor and pots tumble stacked.... where as most illustrations assume a flat floor. I'm intrigued by the spherical one as it is actually a very sophisticated idea, and it would be fun to try (it is also possible that the artist got things wrong!). The spherical one appears in an article on this site https://atlasgreekkilns.arizona.edu/project

Anyway, all good fun! This evening I am relaxing after some hours in the studio turning coffee cup feet and putting on handles!

All the Best,

Peter

I came across your blog and am hoping you might have some advise for me. I used to fire cone 10 reduction with a 11-13 hour firing. I use a very gritty clay but haven’t had any problems with the grit with glazes. Due to circumstances I am now firing cone 10 in an electric kiln. I am using the same clay and glazes and the grit is causing the exterior surface to be very rough after the firing. I adjusted the kiln schedule to be a 10 hour firing with a 30 min soak at cone 10. From reading your blog I may adjust the schedule to be an hour rise from cone 9-10. Do you have any thoughts on why the surface would be rough from reduction to electric?

Cheers,

Meg

Good to hear from you. Making changes is never easy, and I do sympathize about having to move from reduction to oxidation firings due to "life". The electric kiln is very different than gas or wood and that difference can be maddening when what was familiar no longer works, but also the oxidation atmosphere can enable other possibilities too!

My intuition tells me that the clay body being smoother in reduction than in oxidation is due to the increased fluxing that occurs in reduction. More of the silica that is in those lumps and bumps will go into solution in reduction and smooth out. You will probably notice this with glazes too, particularly those that contain iron, these will often move and flow more in reduction as the iron becomes a very active flux.

If you really have no choice but to continue using that clay body, you might have to think about adding a layer of slip or engobe made up of a much finer clay that is applied to the pot when soft leather hard. That is certainly something that was done a lot in distant times to improve the look of coarse clay, or even to imitate porcelain bodies.

If you can, my advice would be to change to a smoother clay body, and probably fire at a slightly lower temperature too. I realize that most people these days seem to be firing at cone 6 with electric kilns, however I still prefer to fire to cone 9 but am considering lowering that by about half a cone to cone 8 and a bit! Cone 8 -9 suits the commercial clay bodies I use, and also my attachment to the look of high temperature glazes. Cone 8 - 9 will be considerably less stressful on kiln elements, kiln shelves and the like and a lot of cone 10 glazes can probably be persuaded to fire lower with a 2 - 3 percent addition of borax frit, or 1 - 2 percent lithium, or maybe a little wood ash if you want to be more adventurous!

I do hope that the change to electric will open up some creative possibilities for you and you will start to enjoy it. Some reduction glazes will work well in oxidation, but look quite different to how they were in reduction. Copper red glazes can give very beautiful pale green in oxidation, and some iron glazes are actually improved by oxidation!

Very best wishes,

Peter

Sorry to be a few days with this reply, things have been a chaotic here!

I'm glad to see that your enthusiasm for Greek style kilns has not disappeared in spite of the major challenge of an unco-operative back... complete with bone spurs and herniated disks! Life certainly can be frustrating (and painful), but it is good to battle onwards as much as possible. I hope you can find an assistant, building kilns is a wonderful thing to do and kilns that are exploring how potting was once done many hundreds of years ago is very educational.

I've had also quite a bit going on from a health point of view over recent years and it has slowed me down a lot, I keep having to adapt to having less physical capabilities as things wear out or go wrong, but I am still potting and learning more as I do!

Very best wishes to you,

Peter

regards and keep the home fires burning. Will

I was amused to read about the Persephone that was 2 inches taller than the Skutt interior, and impressed by your kiln building resourcefulness! I have sometimes contemplated removing the lid from my top loading electric kiln and adding a temporary course of insulating fire bricks around the top to increase it in capacity when some of my work has been too tall. I suspect this might work for a bisque firing, but would probably become unworkable for higher temperatures. I do have a few pots out in the shed awaiting their turn in the wood fired kiln that didn't quite fit in the electric! Hope the carpal tunnel surgery works out well for you. You've probably tried various things already, but I did a few years ago get a lot of help from someone who specialised in deep tissue massage, and he got my right arm going again that had become so bad that I could not hold a pen to do more than painfully sign my name.